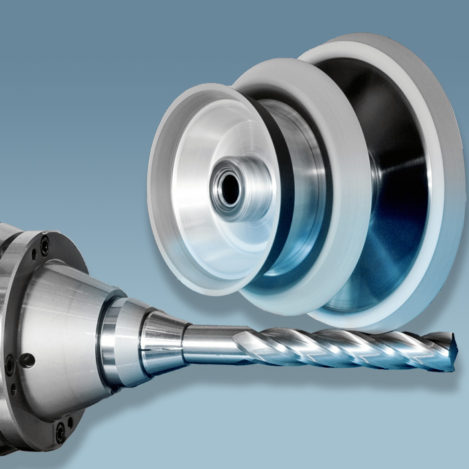

Grinding Wheels MPP's Diamond Wheels

Home » grinding-wheels

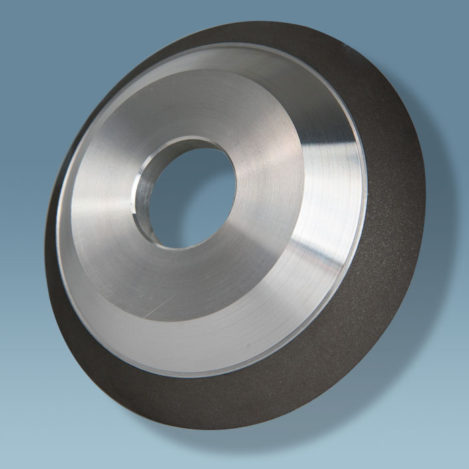

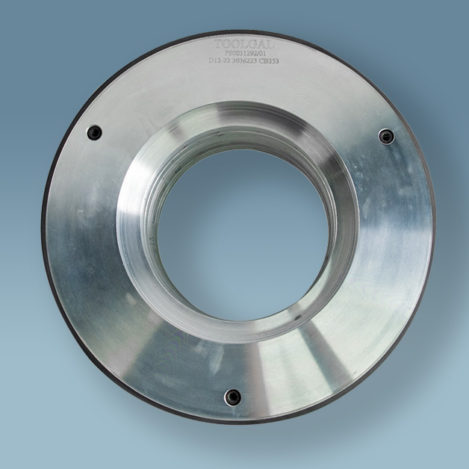

Toolgal Diamond Wheels is an experienced manufacturer of High Quality Diamond and CBN grinding wheels. Toolgal supplies the wheels for several applications:

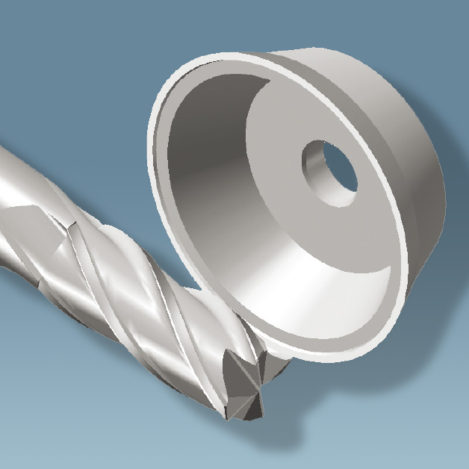

- Carbide Round tools on CNC machines: Flute Grinding, Gash Grinding, end facing, Clearance angle Cylindrical grinding.

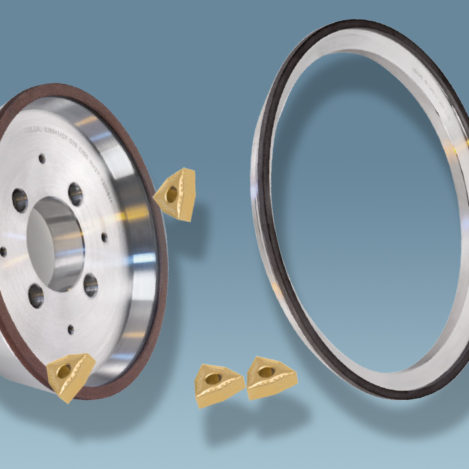

- Insert grinding for machines such as: AGATHON, WENDT, HAAS, WAIDA and EWAG.

- Woodworking saws and tools.

- HSS tools.

- Cut off wheels.

- Many more which can be found in our catalog.

Among Toolgal’s customers’ you can find top Carbide and HSS tools manufacturer such as ISCAR, IMC Group, Vargus and Kennametal. The wheels are sold to the domestic market and are exported to many countries in Europe, America and the Far East.

Toolgal acquired a highly respected reputation in the last 40 years for:

- Production of high quality products

- Full ‘In House’ control along the entire production process (“Powder to Product & quote)

- Devoted customer service, by identifying customer needs and developing tools accordingly.

- Cooperation with our distributors in identifying the markets ever changing needs.

- Cooperation with the Israeli government Chief Scientist Office for special R&D projects.

- Hand on – customer technical support.

STORAGE

Diamond and CBN grinding wheels should be carefully stored in original packaging and the core should be kept oiled.

MACHINES

Machines should be in good working condition, well maintained and free of vibration. Special attention should be given to the spindle which should run true and the spindle bearings which should be in good condition.

WHEEL MOUNTING

After cleaning and checking the mounting arbor and flange, the wheel should be running true to within 0.02 mm.

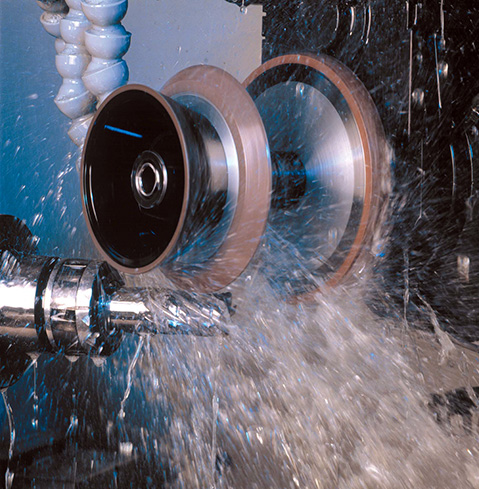

COOLANT

• Synthetic oil – Most popular

• Emulsion (water based)

Water with an added rust inhibitor is sufficient for diamond grinding wheels. The life of CBN grinding tools can be significantly extended by using pure oil yet an emulsion with oil concentration should be sufficient.

CUTTING FLUIDS

Cutting fluids should be used whenever possible when using diamond wheels, to reduce the heat generated by grinding as well as to extend the wheel’s life. If it’s necessary to dry grind, a corret resin-bond wheel should be used.

COOLANT FLOW

The best cooling effect is achieved when the outlet speed of the cooling lubricant is adapted to the peripheral speed of the grinding wheel, and the nozzle opening is only slightly wider than the grinding rim.

A small trickle of coolant occasionally applied, is better than no coolant at all. This causes alternate heating and quenching, which can cause damage to the diamond wheel and carbide tools.

1. Always strictly follow the safety rules prescribed for Toolgal tools as well as the instructions for the use of machines and/or electrical tools. Always strictly keep to safety rules issued by organization responsible for the prevention of accidents.

2. To avoid risks associated with the use of rotating tools it is strongly recommended to use the utmost caution and concentration when working.

3. Always wear correctly sized gloves that allow the sensitivity necessary to operate the tool correctly and give adequate protection in the event of the blade being touched during use.

4. Install only tools in perfect condition that are recommended for the material to be worked and that are suitable for the type of machine used.

5. Do not use cracked or deformed tools.

6. Check that the balancing, keying and centering of rotary tools is carried out correctly.

7. Mount the tool correctly using the proper tightening and adjustment devices.

8. Remove all tightening and adjustment devices before use.

9. Check that the tool rotates in the correct direction.

10. Always use safety glasses or protective screens to protect the eyes.

11. The work area and the area around the machine must be free of obstacles.

12. The work area must be properly lit.

13. Before starting any kind of work, install all the safety devices prescribed by the builder of the machine or power tool.

14. The operator must be at least 18 years old and of the minimum age prescribed by the laws in force. They must be adequately trained in the use of the machine or power tool.

15. Avoid using machines or power tools in the event of any illness or physical condition that may reduce reflexes or awareness and increase exposure to risk.

16. Do not use the machine or power tool under the influence of alcohol or drugs.

Click Here to dowload the FEPA standard

Click here and get our application guide

Israel

Toolgal Head Office, Degania “A” 15120 Israel

Orit Korin

Tel: +972 4 6608014

Fax: +972 4 6752620

E-Mail: [email protected]

Site: a20612-tmp.s165.upress.link

Germany

Yaron Sheffy,

Tel: (+49) 0172 2172283

E-Mail: [email protected]

Switzerland

HOZO GmbH

Maschinen-Schleifmittel

Dorfstrasse 22

3436 Zollbrück

Tel: +41 34 496 72 18

Fax: +41 34 496 72 51

E-mail: [email protected]

China

Shanghai MTEC Precision Tools Co.,Ltd

Room 1506, Zhongzhan Building, No.2959, GuDai Rd., Minhang District

Shanghai, P.R. 201199 China

Tel.: +86 21 52967223, Fax: +86 21 52967223

Contact Person: Mr. Pei Bin Mobile Phone: +862160171238

Netherlands

A one Industrial Diamond & C.B.N

Yossi Shemesh , Amstelveen Turfschip 3 1186XA

Tel: 00-31 207851173

Fax: 00-31 848675666

E-Mail:[email protected]

Skype: yshe999

Poland , Czech Republic, Slovakia

WEZA Aleksander Zak

Alek ,Chorzow ul.Niedziedziniec 14F/4, 41506

Tel: 00-48 48515145990

E-Mail: [email protected]

Spain

Pomdi HERRAMIENTAS DE DIAMANTE, S. A.

Alberto Oliva , MECO Cº de Villanueva, 20 28880

Tel: 00-34 91 8860061

Fax: 00-34 91 8860086

E-Mail: [email protected]

Site: www.pomdi.com

Russian Federat

OOO Intehnika

Godovikova Str., 9, block 25, Moscow 129085

Tel.: 00-7 495 560 4888

Fax: 00-7 495 560 4999

Thailand

KNK INTECH CO.,LTD.

Mr. Nattana Kregnavakul ,Bangna Bangkok 111/47 Soi Lasal 32 10260

Tel: 00-662 7493122

Fax: 00-662 749 3828

E-Mail: [email protected]

United States

TOOLGAL USA INDUSTRIAL CORP

David Ginzburg, Elberton Georgia 283 A Tribble St 30635

Tel: 00-17 062839556

Fax: 00-1706 283 9558

E-Mail: [email protected]

Site: a20612-tmp.s165.upress.link

Our Product Categories:

Flute Grinding

Flute grinding is one of the most costly manufacturing steps for mill, drill and cutter manufacturers, hence the need for constant improvement.

Gash Grinding

Gashing requires higher profile consistency (of the grinding wheel) in comparison to fluting, due to the high edge quality required of carbide tools.

Instert Grinding

Diamond Wheels for Peripheral Grinding of inserts, must be of a high level of geometrical accuracy, with ability of significant material removal.

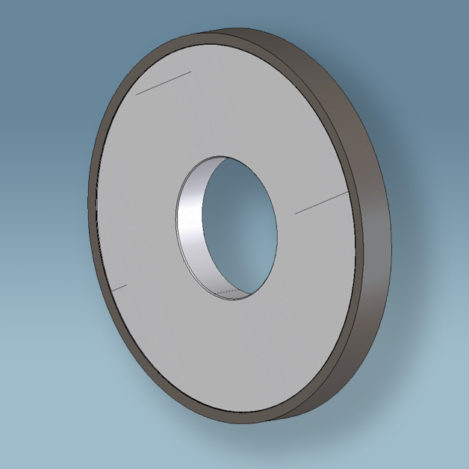

O.D. Grinding

OD (Out Diameter,) Clearance Angel and End Face require wheels which enable the work piece to achieve excellent finishing, maximum surface Quality.

Cylindrical Grinding

The cylindrical grinder is a type of grinding machine used to shape the outside of an object. The cylindrical grinder can work on a variety of shapes; however the object must have a central axis of rotation.

Centerless Wheels

Toolgal supplies a complete range of centerless grinding, polishing and straightening services.

Cut Off Wheels

Toolgal supplies cut off wheels for wet and dry cutting, for Carbide and for HSS. The combination of balanced high quality bodies with high quality bonds and diamond gives Toolgal cut off wheels a market edge