Precise Parts

Home » Precise Parts

MPP utilizes its special machining capabilities for manufacturing small precision tools and parts from a wide range of materials: Tungsten Carbide, Silicon Carbide (SiC), Silicon Nitride (Si3N4), various grades of stainless steel (203, 316, 304 etc…), different ceramic types such as Alumina/ Aluminum Oxide (Al203), Zirconia (ZrO2) and machinable ceramics – (Macor). The parts are used in a wide variety of applications and industries – providing high precision solutions & precise parts to the Semiconductor, Aerospace, Medical, Automotive and other industries.

MPP has more than 40 years of accumulated experience making fine precise parts for custom applications.

MPP’s is proud to offer “build to print” and “build to spec” services by utilizing our inhouse capabilities which will make MPP your preferred one stop shop for precision parts:

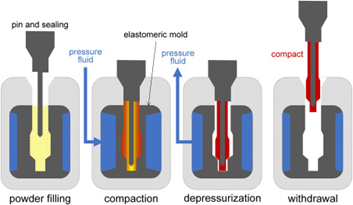

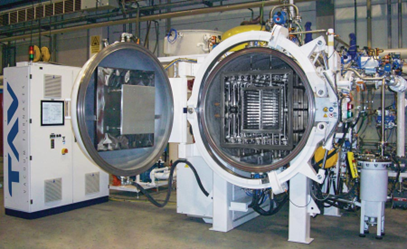

Pressing and Sintering

complete vertical integration- from powder to raw material. Mastering the whole process of hard metals and ceramics

- Self-designed compaction system

- Pressure sintering system

EDM (Electro Discharge Machining)

- Die Sinking

- Wire cutting

- Micro precise hole sinking

- Self designed semi-automated Micro-Sinking systems

- Opto-Computerized automated system for incorporated QC within the production process (Self-designed software & hardware)

Turning and Milling

- CNC Precise machining 4/5 axes

- Multi-function Mill Turn Center

- Highly Precise & accurate milling systems

- “Swiss-Type” milling system

Grinding

Ultra precise CNC 4/5 axes systems

Round & surface grinding systems

Automatic 6 axes systems

Automatic Centerless grinding systems

Self designed & built semi-automated Micro-Grinding systems

Dicing

Automated precise dicing systems

2” Tilted spindle 0⁰ to 15⁰

Self-designed special Jigs

Quality assurance and Control

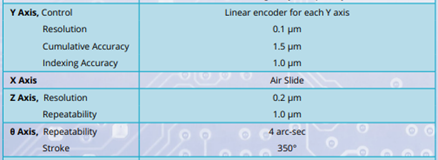

- “NEXIV” – Programable Video Measuring System

- Coordinate Measuring Machine (XYZ)

- OGP – non-contact and multi-sensor dimensional measurement systems

- Confocal microscope/comparators – optical microscope measuring systems

- Microscopes up to 400X

- Self-designed & built automated QC systems

- Professional QA & QC team

- Strict QA Processes & Procedures

Added Value by Choosing MPP

- Knowhow, expertise, experience

- Cutting-edge precision technologies

- Wide array of applications

- Design & draw per spec

- Raw material sourcing & preparation

- Design of the optimal production process

- Private labeling – special packaging

Recent success cases:

- Special Micro Dispensing nozzle from Tungsten carbide with +/-5µ tolerances

- Ultrasonic bonding tool with a “waffle” tip made of an exotic ceramic formulation

- Hydraulic system part made of PH15-5 (Stainless Steel)

- A Titanium made precision part for a medical application

- A Unique tool used for the Electric vehicle battery manufacturing process